+38(067)285 7770

AVIGAN LLC is a dynamic engineering company specializing

in the design and implementation of energy-saving technologies

for enterprises of various industry fields.

So far, our company can offer a range of equipment, technologies and solutions in the area of energy savings and industrial automation that can be applied at the majority of industrial enterprises.

AVIGAN LLC is an official engineering partner of such worldwide leaders as follows:

AVIGAN LLC was founded in 2007

• More than 200 projects have been implemented in different fields of industry and manufacturing;

• Food industry:

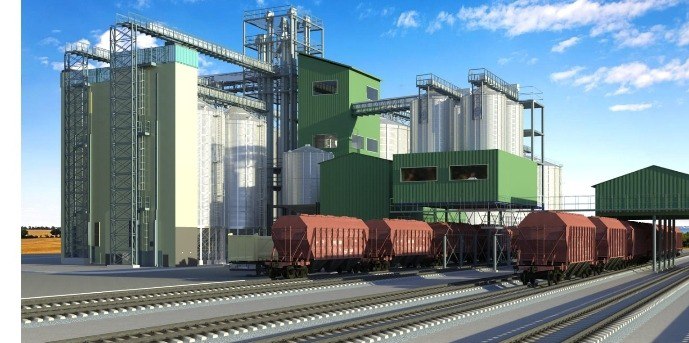

- Oil refineries, Milk processing plants, Fodder factories, Cheese Processing Plants, Soybean Oil Refinery Plants, Grain elevators, Winery plants etc.,

• Recycling

• Pharmaceuticals industry

• Water supply and sewerage

• Process fluids and liquid foodstuff purification systems

• Integrated supply of equipment and processing lines Комплексные поставки оборудования, технологических линий

Electrical and control software design: robotized storages, extrusion lines, twisting machines, wire drawing, paper mills, sunflower seeds and soybean processing with husk and meal pelletizing, etc.

Company’s MES system utilizing both standard clients and Intranet Web interface.

Development of web resources, including online store, CRM-systems, MES - manufacturing execution system CRM - customer relationship management CMM - capability maturity model, model of technological maturity of the organization.

Energy-saving technologies and industrial automation as well as ecological solutions and environmental protection measures can be applied at the majority of industrial enterprises.

- Development of modern automated control system (ACS); control systems for metering and measurement of products and raw materials in the process of production and storage

- Replacement of obsolete and energy-intensiveelectrical equipment, control and measuring devices, industrial controllers (instrumentation and controls) for modern energy-saving equipment from leading European manufacturers.

- Implementation of technologies and solutions for various wastewater treatment facilities including;

Wastewater biological treatment,

Post-purification of sewage water,

Wastewater sludges treatment

Integrated supply of industrial and manufacturing equipment

|

Development and modernization of electricity supply system

RSD - Reserve switching devices MDB - Main Distribution Boards DS - Distribution switchboards CB - Control boards LID - Lead-in distributors FRD - Frequency regulating and control devices PD - Power distribution cabinets RPC - Reactive power compensation panel VCP - Ventilation system control panel

|

Industrial and manufaturing process automation

- Implementation of energy-saving technologies - Fiscal and In-house Metering Systems - Automated control system for management and dispensing of raw materials and products of food production facilities - Automation of Lift devices and Pick-and-place machines - Remote touch system to control process parameters of electrical facilities as well as Water- and Heating-management systems - Automated energy-saving systems for water withdrawal and water supply - Automation and supervisory control of building utilities - Electrical installation work

|

Short list of implemented projects:

|

· Automated

accounting system for milk products at Zhytomyr butter factory Rud. · Automated

accounting system for milk products for TM Milk Doctor. · Automation of

compressor units 180 kW at Kulindorovo bread factory. · Automated

accounting system for storage and transporting of tropical oils at Chornomorsk

oil refinery Ltd. · Automated

monitoring system of processing lines at pharmaceutical factory Interchim Ltd. · Automated

production accounting system at CJSC "Odessa Plant of Sparkling

Wines CAMPARI" · Automation of

paper-making machine at folding carton plant Donetsk-Vtorma LLC. · Reconstruction of

electricity distribution units 0,4 kV and 10 kV as well as electrical

installation work at Kievstar Ltd. · Water pressure maintenance system within city's water supply system Izmail Vodokanal.

|

· Development and implementation of a comprehensive automation system at Soybean Oil Refinery Plant of TM Korolivskiy Smak.

|

Development of technical documentation for industrial, manufacturing, and residential civil facilities according to European standards (IEC)

- Electrical circuits for atomation and power supply

- 3D visualization of construction projects

We design internal power supply and automation of production

AutoCAD, EPLAN, ArhiCAD, REVIT

Our contacts

TEL/VIBER/ WhatsApp UKRAINE :+380672857770